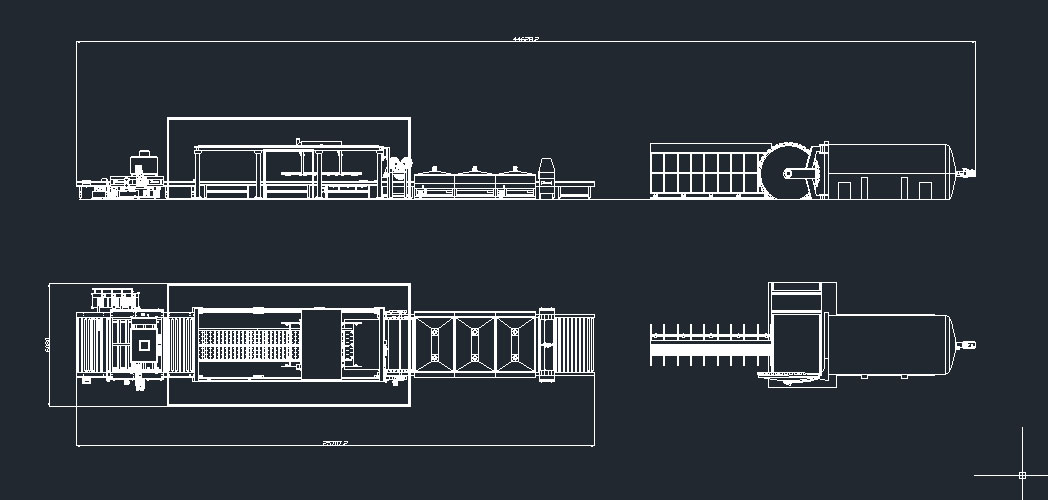

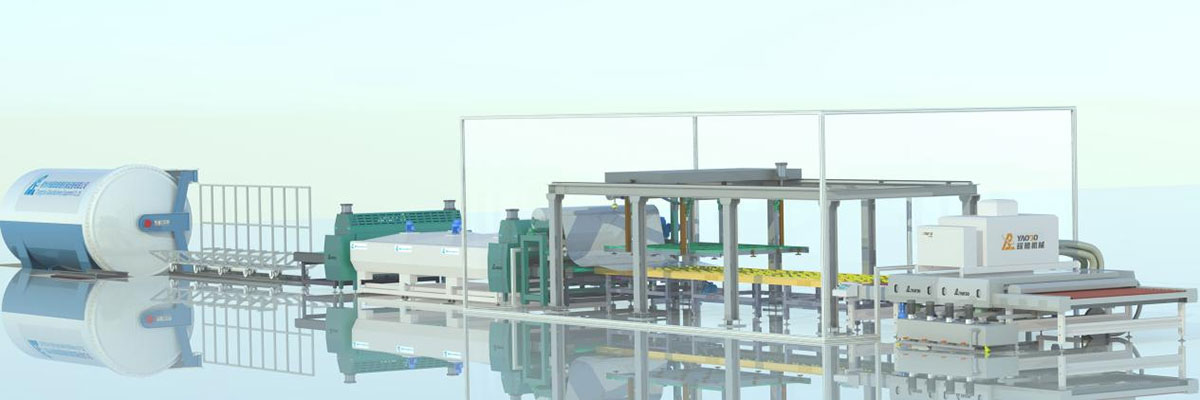

全自动夹层玻璃生产线主要由自动上片台,玻璃清洗干燥机,过渡输送台 (三段),自动预定位机,自动吸盘吊架,合片台,电动PVB胶膜铺摊机,预压机,自动下片台,高压釜等设备组成,该线有以下几大特点:

1、生产效率高: 与半自动夹胶线相比自动夹胶线生产效率更高,可以实现连续生产;

2、自动化控制: 自动夹胶线所有阶段都可以通过自动化控制完成,无需人工干预;

3、可靠性高:自动夹胶线生产过程中使用先进的自动化技术,质量更稳定可靠;

4、生产周期更短:自动夹胶线生产周期更短,可以更快地生产夹层玻璃;

5、全线严格按照安全规范等级及能源节约标准来研发设计和生产,在全球我们能满足严格的需求而设计专门的机器;

6、自行研制开发出软件程序完全能满足各种类及规格的夹层玻璃生产线,并能使玻璃在每段高速传送过程中平滑地加速和减速,衔接性好,玻璃不发生碰撞和留有任何痕迹。自动上片台分单边,双边单工位配置上片;

7、玻璃清洗于燥机设计合理,上部毛刷,胶辊及风刀根据厚度同时升降,较大升程可达到300mm,升降控制可采用人为控制和通过测厚装置自动控制等方式。

8、合片室内自动与定位机通过辊轴传动实现玻璃纵向精确定位,采用同步带传送实现玻璃横向精确定位;

9、在合片室内通过自动吸盘吊架工作吸片进行合片。合片室内自动吸盘吊架根据玻璃长度可简便地设置行走位置,将多片玻璃精确叠合误差<±0.5mm合片台设计可伸缩作业工作台面,电动PVB胶膜可自动放膜和收膜,膜筒数量可1-5卷膜选择配置。预压机更具独特的设计和极高的配置实现玻璃的初始压合成形,加热区通过可控硅实现无触点自动调节加热元件,使PVB膜快速很好的吸温加热,同时主加热区设有热循环系统,促使炉内温度达到均匀。预压机采用独立传动结构及通过大气缸建立上部压力的压合方式均匀地加压和彻底地将玻璃之间的空气排出,确保每组玻璃压合后无错位成形。预压机两根上下压辊之间的间隙调整可选择人为控制和自动测厚装置自动控制等方式;

10、尾端的自动下片台可实现自动将玻璃翻起,便于专用吊具吊装玻璃;

11、配有程序化控制蒸压釜,采用外接线加热元件方式及独特的循环系统和水冷却系统,安全可靠,操作简便,每釜工作循环时间短。通过PLC控制自动定位,直线导轨导向和伺服电机系统;

The fully automatic laminated glass production line is mainly composed of automatic loading table, glass cleaning and drying machine, transition conveying table (three sections), automatic pre-positioning machine, automatic suction cup hanger, laminating table, electric PVB film spreading machine, pre-pressing machine , automatic unloading table, autoclave and other equipment, this line has the following characteristics:

1. High production efficiency: Compared with semi-automatic laminating line, automatic laminating line has higher production efficiency and can realize continuous production;

2. Automatic control: All stages of the automatic glue line can be completed through automatic control without manual intervention;

3. High reliability: Advanced automation technology is used in the production process of automatic lamination line, and the quality is more stable and reliable;

4. The production cycle is shorter: the production cycle of the automatic lamination line is shorter, and the laminated glass can be produced faster;

5. The whole line is developed, designed and produced in strict accordance with safety standards and energy conservation standards. We can design special machines to meet the most stringent requirements in the world;

6. The self-developed software program can fully meet the various types and specifications of the laminated glass production line, and can make the glass accelerate and decelerate smoothly in each high-speed transmission process, with good cohesion, and the glass does not collide or leave any gaps. trace. The automatic loading table is divided into unilateral and bilateral single-station configuration loading;

7. The design of the glass cleaning and drying machine is reasonable. The upper brush, rubber roller and air knife are lifted and lowered at the same time according to the thickness. The maximum lift can reach 300mm. The lifting control can be controlled manually or automatically through the thickness measuring device.

8. The automatic and positioning machine in the assembling room realizes precise vertical positioning of glass through roller shaft transmission, and uses synchronous belt transmission to realize precise horizontal positioning of glass;

9. In the assembling room, the assembling is carried out through the automatic suction cup hanger working suction piece. The automatic suction cup hanger in the lamination room can easily set the walking position according to the length of the glass, and the precise lamination error of multiple pieces of glass is <±0.5mm. , The number of film tubes can be configured from 1-5 rolls. The pre-pressing machine has a unique design and extremely high configuration to realize the initial pressing and forming of the glass. The heating zone realizes the non-contact automatic adjustment of the heating element through the thyristor, so that the PVB film can absorb and heat quickly and well. At the same time, the main heating The zone is equipped with a thermal circulation system to promote uniform temperature in the furnace. The pre-pressing machine adopts an independent transmission structure and a pressing method of establishing upper pressure through a large cylinder to uniformly pressurize and completely discharge the air between the glasses to ensure that each group of glasses is formed without misalignment after pressing. The gap adjustment between the two upper and lower rollers of the pre-press can be controlled manually or automatically controlled by the automatic thickness measuring device;

10. The automatic unloading table at the end can automatically turn up the glass, which is convenient for hoisting the glass with special lifting tools;

11. Equipped with programmable control autoclave, using external wiring heating elements and unique circulation system and water cooling system, it is safe and reliable, easy to operate, and the working cycle time of each kettle is short. Automatic positioning, linear guide rail guidance and servo motor system controlled by PLC;