用于匹配双边磨使用;

进片段有两道预喷淋,减少带入主机的玻璃粉,减少玻璃粉对设备的腐蚀,延长设备使用寿命;

PLC控制系统,配有编码器等传感器,可通过设置相应的厚度和速度,控制系统可自动控制;

水路部分有多重过滤,尽可能的保持喷淋到玻璃表面的水的洁净度;

喷淋管安装有大量喷头,喷头型号为9515,喷射出的水为扇形,可有效覆盖全部玻璃,无死角,且喷头口较大,不易被玻璃粉及其他污染物堵塞;

毛刷电机使用减速机,输出扭矩大,避免小皮带轮带动大皮带轮,减少传动皮带的打滑和磨损,延长皮带使用寿命;

毛刷材质为尼龙丝材质,转速500r/min,能更有效的清洁玻璃表面污染物;

一道上毛刷材质为尼龙0.08mm的,清洗LOW-E玻璃时使用且不划伤膜层;

配备有3对风刀,风刀使用铝合金一次成型,变形小,刀口均匀误差小,保证刀口间隙误差小于±0.2mm,更好的吹干玻璃;

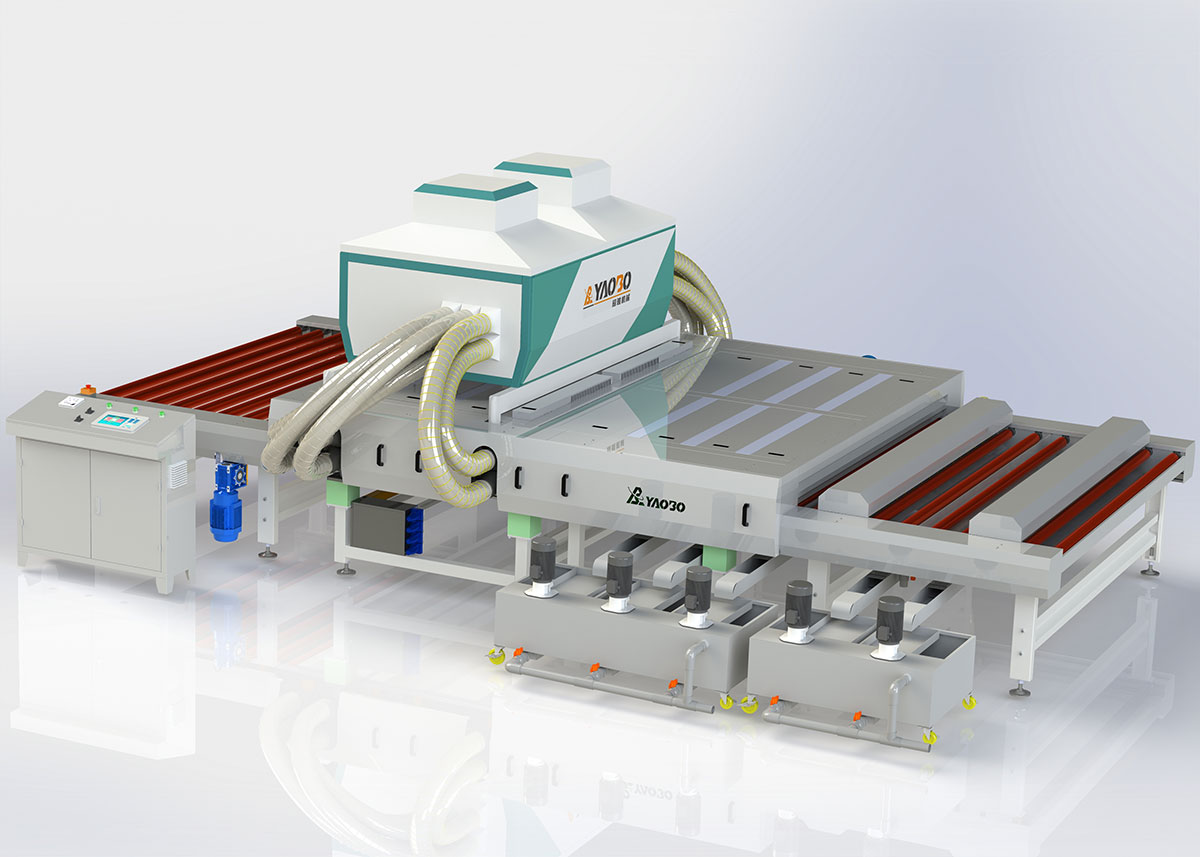

风机箱安装在设备上架上方,能更有效的节约厂房空间;

风机箱里有两台风机,可两头出风,洗小片玻璃的时候可以只开一台风机,起到节能节耗的作用,

一道风刀配备有加热器,在冬天或者潮湿天气开启,有助于吹干玻璃;

水箱分为两个独立的水箱,个水槽配有加热器,有助于提高玻璃洁净度

升降行程为0-300mm,方便保养和维修;

水箱底部安装有拖轮,方便拖动清理水箱;

sed for matching glass double straight-line edger ;

There are two pairs of water pre-sprays in the entering section to reduce the pollutants brought into the main machine, reduce the corrosion of glass powder on the equipment, and extend the service life of the equipment;

PLC control system, equipped with encoders and other sensors, can automatically control the system by setting corresponding thickness and speed;

The water circuit has multiple filters to keep the water sprayed on the glass surface as clean as possible; The spray pipe is equipped with many nozzles, with a nozzle model of 9515, and the sprayed water is fan-shaped and can effectively cover the entire glass without dead corners. In addition, the nozzle opening is large and not easily blocked by glass powder or other pollutants;

The brush motor uses a reducer with high output torque to avoid the small pulley driving the large pulley, reducing belt slip and wear, and prolonging belt service life.

The brush material is made of nylon wire and its rotation speed is 500r/min, which can effectively clean the surface pollutants of glass; The last set of brushes is made of 0.08mm nylon wire to avoid scratching the film layer when cleaning LOW-E glass

There are three sets of air knives, and they are made of aluminum alloy in one piece, with small deformation, uniform blade edge and small error to ensure that the blade spacing error is less than ±0.2mm, which is better for blowing the glass dry;

The fan box is installed above the equipment rack to effectively save factory space;

The last set of air knives is equipped with a heater, which can be turned on in winter or humid weather to help dry the glass;

The final sink of the tank is equipped with a heater to help improve the clarity of the glass;

The lifting stroke is 0-300mm, which is convenient for maintenance and repair;

The bottom of the water tank is installed with four wheels, which is convenient for dragging and cleaning the water tank.